Inconel 600/601/625/718 Pipes & Tubes Manufacturer

Delta Steel specializes in manufacturing 17-4 PH Round Bars in India.

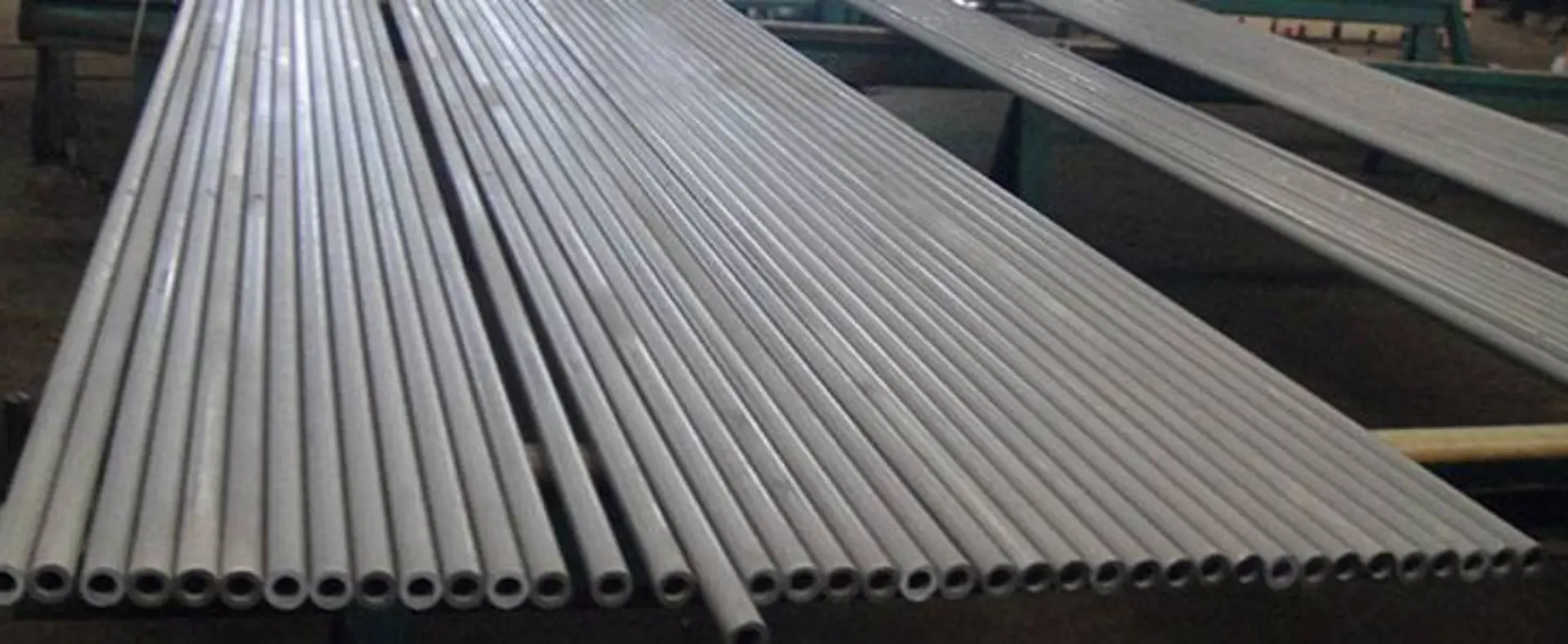

Delta Steel is actively engaged in manufacturing and supplying high-quality Inconel 600, 601, 625, and 718 pipes and tubes. These pipes and tubes are made using premium alloy materials, which enhance their strength and overall quality. As a customer-focused supplier, we offer these products in various sizes, specifications, standards, and forms, including custom-made options. Our products meet international quality standards such as ASME, ASTM, and API, ensuring reliability and performance.

ASTM B167 Alloy 601 Seamless Pipes Supplier, Inconel 601 Tubes Exporter, ASTM B983 Inconel 718 Pipes, ASTM B516 Inconel Alloy 600 Welded Tube, ASME SB444 Inconel Alloy 625 Seamless Tubing, UNS N06600 Welded Pipes, Inconel 600 Seamless Tube, Inconel Pipes Manufacturer in India.

Inconel 600 is a nickel-chromium alloy known for its excellent resistance to oxidation at high temperatures. It also offers strong protection against carburizing environments and chloride-containing atmospheres. This non-magnetic alloy has excellent mechanical properties.

Inconel 601 is another nickel-chromium alloy, valued for its heat and corrosion resistance. It is particularly notable for its outstanding ability to resist oxidation at high temperatures, making it ideal for demanding applications.

Inconel UNS N06625 ERW Tubing, DIN 2.4816 / 2.4851 ERW Pipes Trader, UNS N07718 Seamless Tubes Stockists, Inconel 718 Tubes, Alloy 625 Seamless Tube, Inconel UNS N06601 Welded Pipes Dealer, DIN 2.4856 / 2.4668 Tubing, Inconel Tubes Supplier in India.

Inconel 625 is a nickel-based superalloy known for its excellent strength and resistance to extremely high temperatures. It also offers strong protection against oxidation and corrosion, handling a wide range of temperatures and high stress levels. Inconel 718 is another nickel-based alloy, containing molybdenum and chromium, designed to resist highly corrosive environments, pitting, and crevice corrosion. It offers excellent tensile strength, yield strength, and creep resistance, even at high temperatures.

Today, our Inconel 600, 601, 625, and 718 pipes and tubes are widely used in various industries like heat exchangers, pulp and paper, condensers, petrochemicals, pharmaceuticals, construction, and seawater applications. To ensure top quality, we thoroughly test these products, including PMI, flattening, and micro tests. We provide relevant certification like MTC as per EN 10204/3.1b and radiography reports. Packaging is done according to client specifications.

600/601/625/718 Inconel Pipes and Tubes Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

|---|---|---|---|---|---|---|---|

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

| Inconel 601 | 2.4851 | N06601 | NCF 601 | NA 49 | XH60BT | NC23FeA | NiCr23Fe |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb |

| Inconel 718 | 2.4668 | N07718 | – | – | – | – | – |

Inconel 600/601/625/718 Pipes and Tubes Other Types

Inconel Alloy Seamless Pipes

ASTM B167 Inconel 600 Seamless Pipes, UNS N06600/ N06601 / N06625 / N07718 Seamless Pipes, DIN 2.4816 Seamless Pipes, ASME SB444 Inconel Alloy 625 Seamless Piping

Inconel Alloy Seamless Tubes

ASME SB167 Inconel Alloy 600 Seamless Tube, Inconel 601 Seamless Tubing, DIN 2.4816 Seamless Tubes, UNS N06601 / N06625 Seamless Tube

Inconel Alloy Welded Pipes

Inconel 600 Welded Pipes, UNS N06600/ N06625 Welded Pipe, ASTM B517 Inconel Alloy 601 Welded Pipes, B705 Inconel 625 Welded Pipe, B983 Inconel 718 Welded Pipes

Inconel Alloy Welded Tubes

DIN 2.4816 / 2.4856 Welded Tubing, ASME SB983 Inconel 718 Welded Tube, UNS N06600 Welded Tube, B167 Inconel 601 Welded Tubes, SB704 Inconel 625 Welded Tubes

Inconel Alloy ERW Tubes

UNS N06600 / N06601 ERW Tubes, Inconel 600 / 601 ERW Tubing, Alloy 625 ERW Tubes, DIN 2.4816 ERW Tube, Alloy 718 ERW Tubing

Inconel Alloy ERW Pipes

UNS N06600 / N06601 ERW Tubes, Inconel 600 / 601 ERW Tubing, Alloy 625 ERW Tubes, DIN 2.4816 ERW Tube, Alloy 718 ERW Tubing

Specification of Inconel Seamless Welded Pipes And Tubes

Inconel Pipe Specification : ASTM B167, B517, B983, B444, B705 / ASME SB167, SB517, SB983, SB444, SB705

Inconel Tube Specification : ASTM B516 / ASME SB516, ASTM B704 / ASME SB704, ASME SB983

Standard : ASTM, ASME and API

Tube Size : 15″NB – 150″NB

Thickness Range : 6.35 mm OD upto 254 mm OD in 0.6 TO 20 mm thickness.

Type : Seamless / ERW / Welded / Fabricated Pipes

Form : Round, Square, Rectangular, Oval, Hydraulic Etc

Length : Single Random, Double Random & Required Length

End : Plain End, Beveled End, Treaded

End Protection : Plastic Caps

Inspection, Test Reports : Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports, Destructive Test Report, Non Destructive Test Reports

Packing : Packed in Wooden Boxes, Plastic Bags, Steel Strips Bundled, or as per Customers Requests

Specials : Sizes and Specifications other than above can be manufactured on request

Chemical Composition of Inconel Alloy Seamless / Welded Pipes and Tubes

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

|---|---|---|---|---|---|---|---|---|

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

| Inconel 601 | 0.10 max | 1.0 max | 0.5 max | 0.015 max | 1.0 max | Balance | 58.0 – 63.0 | 21.0 – 25.0 |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | – | 5.0 max | 58.0 min | 20.0 – 23.0 |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015 max | 0.30 max | – | 50.00 – 55.00 | 17.00 – 21.00 |

Mechanical Properties of Inconel Alloy 600/601/625/718 Pipes and Tubes

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|---|

| Inconel 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

| Inconel 601 | 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

| Inconel 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

| Inconel 718 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 482 | 45 % |

People Also Searched for

inconel 625 pipe price list, inconel 600 pipe price, inconel 601 tube manufacturers, inconel 718 tubing, inconel pipe weight chart, inconel 600 welded tube, inconel 600 tube manufacturers, inconel 625 seamless pipe manufacturer, inconel 625 pipe dimensions, inconel 601 pipe manufacturers in india, inconel 625 tubing specifications, inconel 600 pipe suppliers in india, inconel 601 tubing, inconel 600 tubes, alloy 625 pipes, inconel 600 pipe, inconel 625 round tube, inconel 718 tubing, inconel alloy 601 seamless pipe, inconel 600 tubing, inconel 625 tubing suppliers, alloy 601 seamless tubing, inconel 600 seamless pipe, inconel tube weight calculator, inconel 625 tubing, inconel 601 seamless pipe supplier, inconel 625 pipe suppliers, inconel 718 seamless tube, inconel 601 pipe suppliers in india, inconel 600 pipe suppliers in mumbai, inconel 600 pipe manufacturers in india, inconel 625 tube, alloy 601 pipes, inconel 601 welded tube price, inconel 718 seamless tube, inconel 625 exhaust tubing, inconel alloy 718 pipes, inconel 625 seamless pipe manufacturer, inconel 718 tube suppliers, inconel 601 pipe, inconel 600 tubing suppliers, inconel 625 pipe price list, inconel 600 pipe manufacturers, alloy 601 seamless pipe, inconel 625 pipe price, alloy 625 pipe specification, alloy 600 pipe.

Industrial Services

Consult Broshure

Nemo enim ipsam quiautas voluptas sit aspernatur quia untur magni dolores eos.