ASTM A182 Gr F1 Flanges Manufacturer

ASTM A182 Gr F1 Flanges Suppliers

F1 A182 Alloy Steel Flanges are made from alloy steel and are typically used in forming wrought products. This material is designed for use in the annealed condition, and its ASTM designation is F1, with the UNS number K12822.

A182 F1 Cl2 Pipe Flanges have very low electrical conductivity compared to other wrought alloy steels. They also have moderate embodied energy and cost. A182 F1 material is specified for forging and is commonly used in high-temperature applications to produce bare forgings or machined products.

F1 Steel Plate Flanges are a cost-effective solution for applications where raised faces and hubs aren’t needed, particularly in low-pressure or ambient temperature settings.

ASTM A182 F1 Lap Joint Flanges consist of two parts and are similar to weld-neck and loose slip-on flanges. These flanges have the benefit of being able to swivel around the pipe or stub end, making installation easier.

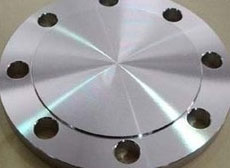

ASTM A182 Gr F1 Blind Flanges are solid disks that block off a pipeline or stop flow. They have mounting holes and gasket sealing rings for secure attachment.

A182 Gr F1 Threaded Flanges, also known as screwed flanges, have internal threads that match the male threads of the pipe for easy connection.

A182 Grade F1 Socket Weld Flanges were initially developed for small, high-pressure pipes. They offer equal static strength to Slip-On flanges but have 50% more fatigue strength than double-welded Slip-On flanges.

SA 182 Gr F1 Slip-On Flanges, also called SO flanges, slide over the pipe and have an internal design slightly larger than the pipe.

SA182 F1 Forged Flanges are used to connect pipes, valves, pumps, and other machinery. These flanges strengthen the connection and provide a secure link between different parts of the system.

ASTM A182 Gr F1 Flanges Material Specification Chart

| Specifications | ASTM A182 / ASME SA182 |

| Size | 1/2″ (15 NB) to 48″ (1200NB) |

| Standards | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

Price of SA 182 Gr F1 Plate Flange

| Type | Description | USA FOB Price | Malaysia FOB Price | Europe FOB Price | Singapore FOB Price | Saudi Arabia (KSA) FOB Price | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Unit Per mtr | Unit Per mtr | Unit Per mtr | Unit Per mtr | Unit Per mtr | |||||||

| ASTM A182 F1 Flanges | Size : 12″NB x 300LB WNRF , | US $ | 250.2 | Malaysia Ringgit | 1018.31 | Euro | 210.17 | Singapore Dollar | 335.27 | Saudi Riyal | 938.25 |

ASME SA182 F1 Cl2 flanges Types

F1 A182 Flange

A182 F1 Cl2 Blind Flange

ASTM A182 Gr F1 Flange

ASTM A182 Gr F1 Flange

A182 Grade F1 Plate Flange

SA 182 Gr F1 Flanges

A182 F1 Cl2 Blind Flange Chemical Composition Chart

| Grade | C | Mn | Si | P | S | Cr | Mo |

| Alloy Steel F1 | 0.15 max | 0.3-0.6 | 0.5 | 0.03 | 0.03 | 4-6 | 0.44-0.65 |

Equivalent Of ASTM A182 Gr F1 Flanges

| STANDARD | UNS | DIN WERKSTOFF NR. | DIN |

| Alloy F1 | K12822 | 1.5415 | 15M03 |

SA 182 Gr F1 Slip on Flange Mechanical Properties Analysis

| Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 275 | 485 | 20 % |

ASTM A182 Gr F1 Flanges Pressure Rating

| Temperature °F | Class 900 | Class 150 | Class 600 | Class 400 | Class 1500 | Class 300 | Class 2500 |

| -20 to 100 | 2085 | 265 | 1390 | 925 | 3470 | 695 | 5785 |

| 200 | 2035 | 260 | 1360 | 905 | 3395 | 680 | 5660 |

| 300 | 1955 | 230 | 1305 | 870 | 3260 | 655 | 5435 |

| 400 | 1920 | 200 | 1280 | 855 | 3200 | 640 | 5330 |

| 500 | 1865 | 170 | 1245 | 830 | 3105 | 620 | 5180 |

| 600 | 1815 | 140 | 1210 | 805 | 3025 | 605 | 5040 |

| 650 | 1765 | 125 | 1175 | 785 | 2940 | 590 | 4905 |

| 700 | 1705 | 110 | 1135 | 755 | 2840 | 570 | 4730 |

| 750 | 1595 | 95 | 1065 | 710 | 2660 | 530 | 4430 |

| 800 | 1525 | 80 | 1015 | 675 | 2540 | 510 | 4230 |

| 850 | 1460 | 65 | 975 | 650 | 2435 | 485 | 4060 |

| 900 | 1350 | 50 | 900 | 600 | 2245 | 450 | 3745 |

| 950 | 845 | 35 | 560 | 375 | 1405 | 280 | 2345 |

| 1000 | 495 | 20 | 330 | 220 | 825 | 165 | 1370 |

A182 F1 Cl2 Weld Neck Flanges Weight Chart

| Pipe Normal Diam. | O.D. Flange | Thk. Of Flange Min | Diam. of Hub | Diameter of Raised Face | Length Hub.Y | Thread Length | Diam. of Bolt Circle | Diam. of Bolt Holes | Number of Bolts | Diam. of Bolts (inch) | KG | LB | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| inch | dn | O | C | X | G | Y | T | BC | BH | BN | BD | ||

| 1/2″ | 15 | 89.00 | 11.20 | 30.20 | 35.10 | 15.70 | 15.70 | 60.50 | 15.80 | 4 | 1/2″ | 0.4 | 0.9 |

| 3/4″ | 20 | 98.50 | 12.70 | 38.10 | 42.90 | 15.70 | 15.70 | 69.90 | 15.80 | 4 | 1/2″ | 0.7 | 1.5 |

| 1″ | 25 | 108.00 | 14.20 | 49.30 | 50.80 | 17.50 | 17.50 | 79.30 | 15.80 | 4 | 1/2″ | 0.8 | 1.8 |

| 1-1/4″ | 32 | 117.50 | 15.70 | 58.70 | 63.50 | 20.60 | 20.60 | 88.90 | 15.80 | 4 | 1/2″ | 1.2 | 2.6 |

| 1-1/2″ | 40 | 127.00 | 17.50 | 65.00 | 73.20 | 22.40 | 22.40 | 98.60 | 15.80 | 4 | 1/2″ | 1.5 | 3.3 |

| 2″ | 50 | 152.50 | 19.10 | 77.70 | 91.90 | 25.40 | 25.40 | 120.70 | 19.10 | 4 | 5/8″ | 2.3 | 5.1 |

| 2-1/2″ | 65 | 178.00 | 22.40 | 90.40 | 104.60 | 28.40 | 28.40 | 139.70 | 19.10 | 4 | 5/8″ | 3.7 | 8.1 |

| 3″ | 80 | 190.50 | 23.90 | 108.00 | 127.00 | 30.20 | 30.20 | 152.40 | 19.10 | 4 | 5/8″ | 4.1 | 9 |

| 3-1/2″ | 90 | 216.00 | 23.90 | 122.20 | 139.70 | 31.80 | 31.80 | 177.80 | 19.10 | 8 | 5/8″ | 5.1 | 11.2 |

| 4″ | 100 | 228.50 | 23.90 | 134.90 | 157.20 | 33.30 | 33.30 | 190.50 | 19.10 | 8 | 5/8″ | 5.9 | 13 |

| 5″ | 125 | 254.00 | 23.90 | 163.60 | 185.70 | 36.60 | 36.60 | 215.90 | 22.40 | 8 | 3/4″ | 7 | 15.4 |

| 6″ | 150 | 279.50 | 25.40 | 192.00 | 215.90 | 39.60 | 39.60 | 241.30 | 22.40 | 8 | 3/4″ | 8.4 | 18.5 |

| 8″ | 200 | 343.00 | 28.40 | 246.10 | 269.70 | 44.50 | 44.50 | 298.50 | 22.40 | 8 | 3/4″ | 13 | 28.6 |

| 10″ | 250 | 406.50 | 30.20 | 304.80 | 323.90 | 49.30 | 49.30 | 362.00 | 25.40 | 12 | 7/8″ | 18 | 39.5 |

| 12″ | 300 | 482.50 | 31.80 | 365.30 | 381.00 | 55.60 | 55.60 | 431.80 | 25.40 | 12 | 7/8″ | 29 | 64 |

| 14″ | 350 | 533.50 | 35.10 | 400.10 | 412.80 | 57.20 | 57.20 | 476.30 | 28.50 | 12 | 1″ | 39 | 86 |

| 16″ | 400 | 597.00 | 36.60 | 457.20 | 469.90 | 63.50 | 63.50 | 539.80 | 28.50 | 16 | 1″ | 47 | 103 |

| 18″ | 450 | 635.00 | 39.60 | 505.00 | 533.40 | 68.30 | 68.30 | 577.90 | 31.80 | 16 | 1 1/8″ | 57 | 126 |

| 20″ | 500 | 698.50 | 42.90 | 558.80 | 584.20 | 73.20 | 73.20 | 635.00 | 31.80 | 20 | 1 1/8″ | 76 | 167 |

| 24″ | 600 | 813.00 | 47.80 | 663.40 | 692.20 | 82.60 | 82.60 | 749.30 | 35.10 | 20 | 1 1/4″ | 97 | 214 |

Industrial Services

Consult Broshure

Nemo enim ipsam quiautas voluptas sit aspernatur quia untur magni dolores eos.